Amity 2500 Scrub Harvesters

Amity Technology’s small and mid-size harvesters, like the 2500 Harvester, configured as a 4 row 30″ or 8 row 22″ unit delivers clean, whole beets efficiently and effortlessly. Engineered with simple effective adjustments, the 2500 is adaptable to all conditions.

More sugar Beet

Easy pinch point adjustments on Amity Technology harvesters help to pull more taproot in dry conditions and less mud in wet conditions.

Lifter Wheels

Amity Technology’s adjustable lifting struts, lift more clean whole beets in dry hard soils, as well as in wet sticky soils while minimizing excess soil entering the harvester. No need to separate what you don’t ingest.

Amity lifting struts are available in numerous configurations, including solid, single, or dual rock protected. All lifting struts are available with top or bottom scrapers.

Service and Support

With the best dealer network, Amity Technology parts and service are available when you need them most!

Solid and Rock Paddles

Solid or optional rock paddles, capable of flexing for rock protection, move the beets from the lifting wheels.

Solid Paddle

Rock Paddle

Tank and Elevator

The 3.5 ton tank on 2500 harvesters is available with single or dual web 50 mm or 56 mm rod driven chains or the latest 55 mm High Profile belt driven Chain. Optional 30″ extension moves your truck or cart out for clearance.

Single Belted Chain

Double Belted Chain

High Profile Chain

Move Those Beets

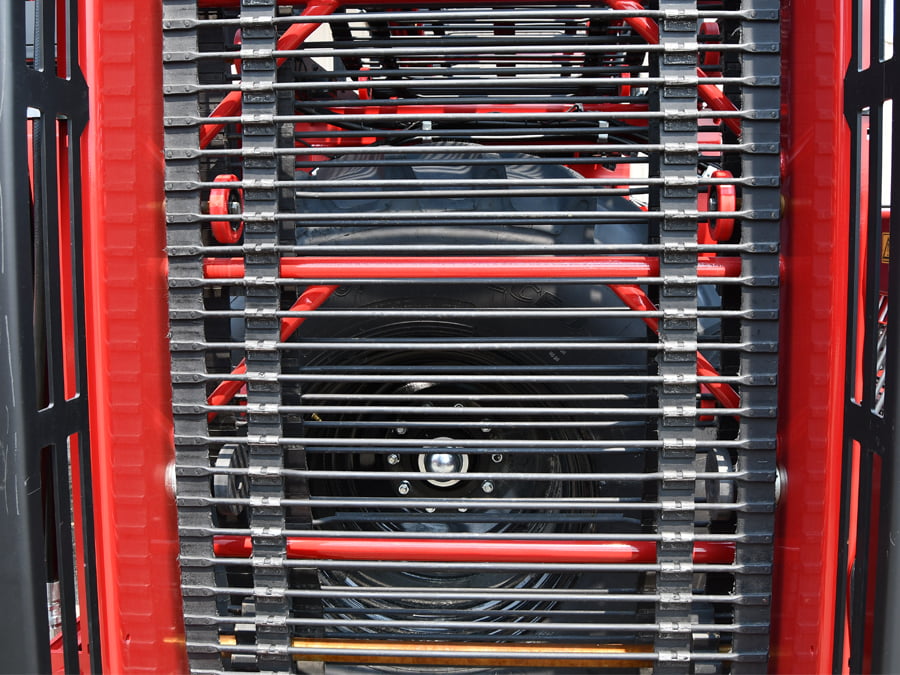

Apron chains are available using 1/2″ or 5/8″ belt or hook chain, most often in 42″ or 56.5″ configurations.

Return to Center

The Amity 2500 Harvester has optional JD Touchset™ steering with return to center.

Greater Volume

Single or dual motor hydraulically driven scrub chains available with 50, 56, or the latest 55mm High Profile belted Chain efficiently move beet yields of 35 tons per acre at speeds up to 5.5 mph. The 55mm High Profile Chain configuration requires dual motor drive.

Field-Proven Solutions™

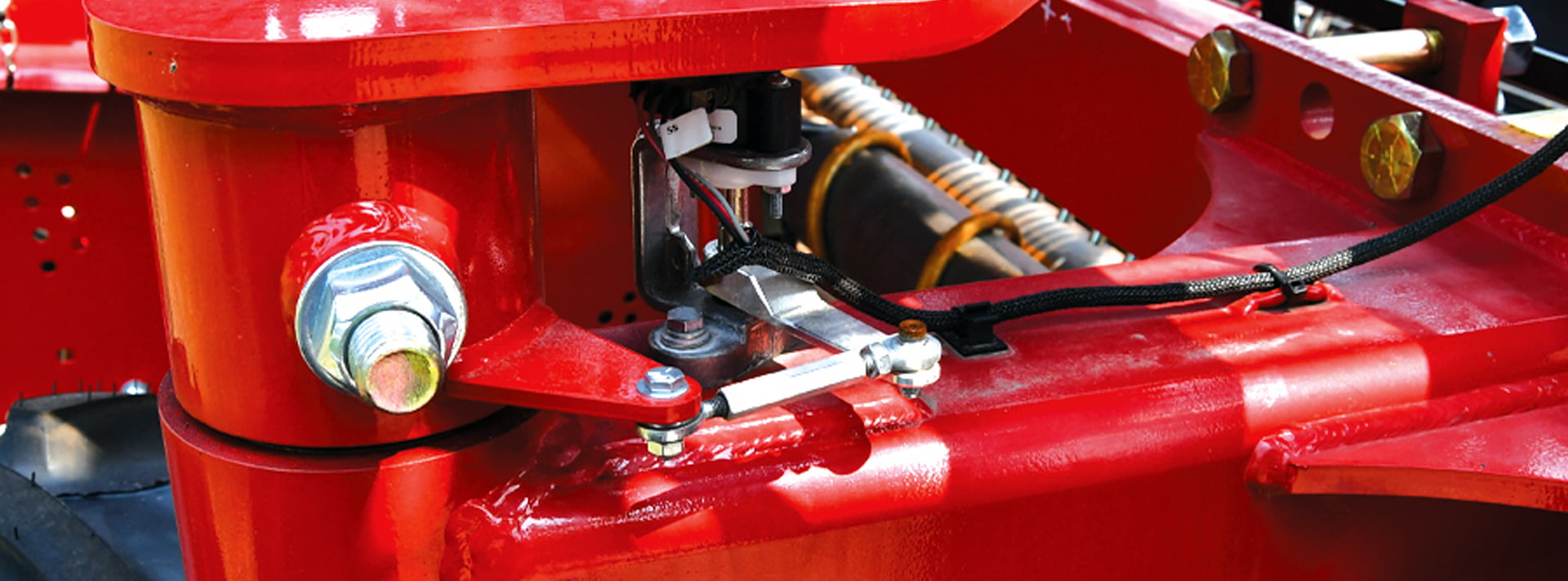

Active Depth Control

Active Depth Control (ADC) on Amity harvesters continuously monitors harvesting depth and controls the hitch and rear cylinders to match harvesting depth across the machine.

ADC is a key component in reducing tare and maximizing root yield. New ISOBUS compatibility delivers diagnostic tools ensuring your harvest continues on time. ADC can be controlled from any ISOBUS terminal, allowing for fewer screens in the tractor.

*ADC cannot be used with steerable struts

** Restrictions may apply. Consult with your dealer.

Carrying Struts

11.2 x 24

23.5/55-26

710/40R22.5

Rigid

- Dual Tire: 11.2 x 24 for ADC

- Single Tire: 710/40R22.5 for ADC

Steerable

- Rear Dual Tire: 11.2 x 24

- Single Tire: 23.5/55-26

Shields with Gas Shocks

Shields with gas shocks provide easy access to working components.

2500 Harvester Features

Apron Chain

Amity harvesters utilize an apron chain between the lifter wheels and the grabrolls, transferring the crop through the harvester and removing a majority of the dirt.

Row Finder

The Amity row finder is a simple, effective tool to keep your harvester on the row. The row finder also has a backup feature that allows backup without lifting the machine or damaging the row finder.

Row Finder

Belt driven front grab rolls are easily adjusted to match aggressiveness to the conditions. They are available in plain, hard surfaced, or poly coated.

PTO Hanger

The PTO hanger keeps the PTO shaft off the ground and clean.

2500 Harvester | 2500 Scrub |

|---|---|

| Number of Rows | 6 to 8 |

| Row Spacing | 20-30” (45-76.2 cm) |

| Total Weight | 22,500 lbs (10.2 MT) |

| Drawbar | |

| Vertical Load | 7,500 lbs (3.4 MT) |

| Length | 20’ 6” (6.2 m) |

| Transport Width | |

| (with boom down) | 19’ 6” (5.9 m) |

| Operating Width | |

| (with boom up) | 25’ (7.6 m) |

| Height | 13’ 10″ (4.2 m) |

| Tank Capacity | 3.5 tons (3.2 MT) |

| Tractor Requirements (minimum): | |

| Power (PTO) | 200 hp (149.1 kW) |

| PTO Speed | 1,000 rpm |

| Hydraulic | |

| Capacity | 30 gpm (113.6 lpm) |

| Pressure | 2,700 psi (18615.8 kPa) |